Materials

This page provides some background information on the material models available in millalyzer. Each section lists the primary or standard names of the alloys along with some equivalent material designations which may be vendor trade names or national standards, so that a text search on this page may be used to find the material name. Note that some specifications, such as the AISI/SAE designation AISI 420 cover a fairly wide range of compositions that split into many different EN materials. The equivalence is therefore not precise.

Aluminium alloys

Very soft wrought aluminium alloys (pure aluminium, AlMg1, AlMg3, 1000- and 3000-series) are not suitable for machining. These materials hardly form distinct chips but tend to gum up tools and throw large burrs. Other than that, most aluminium alloys machine without much difficulty. The higher strength alloys are very attractive for machined components, because their strength and corrosion resistance is close to, or slightly better than that of mild steels.

Very soft wrought aluminium alloys (pure aluminium, AlMg1, AlMg3, 1000- and 3000-series) are not suitable for machining. These materials hardly form distinct chips but tend to gum up tools and throw large burrs. Other than that, most aluminium alloys machine without much difficulty. The higher strength alloys are very attractive for machined components, because their strength and corrosion resistance is close to, or slightly better than that of mild steels.

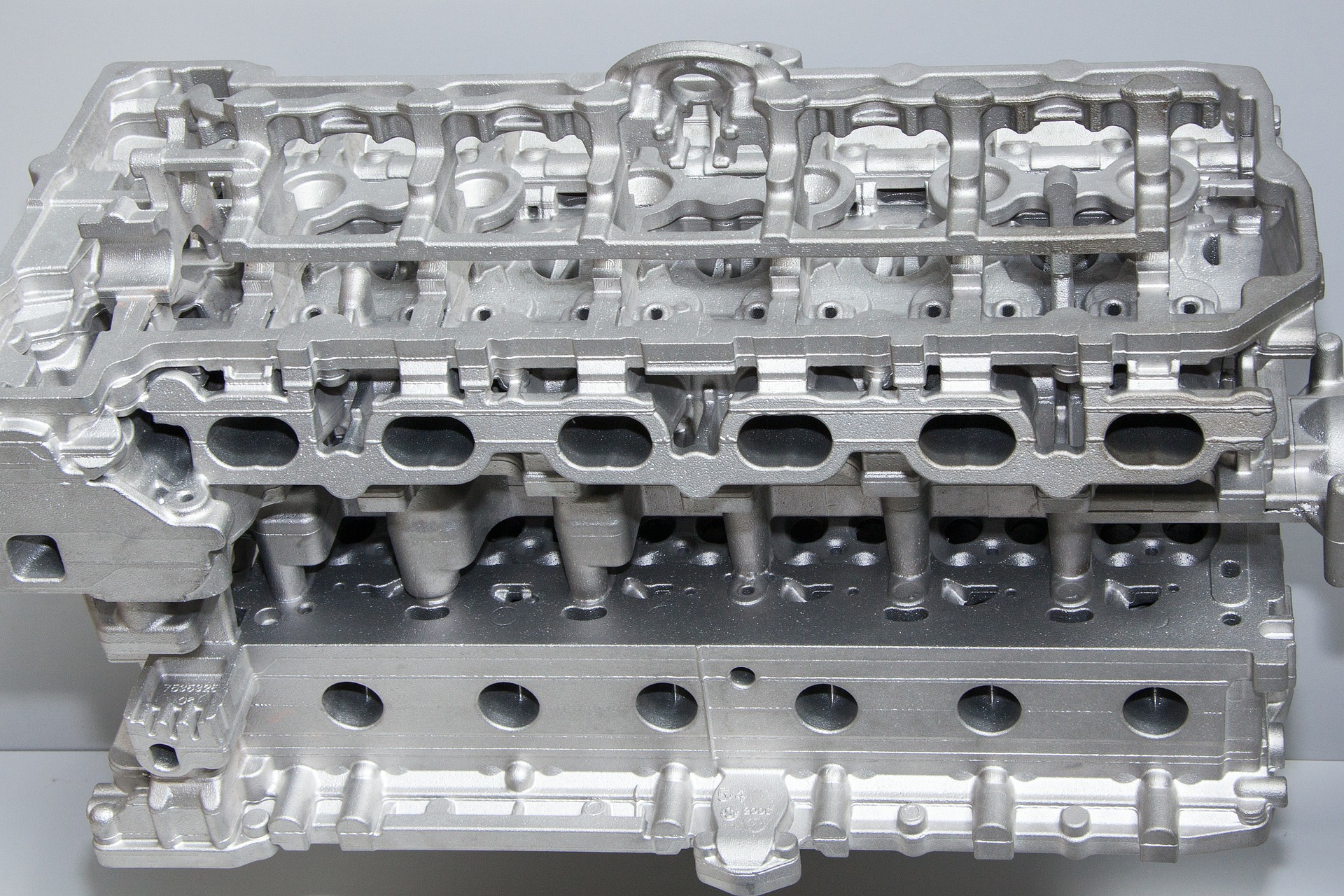

Aluminium alloys fall into two broad categories, wrought alloys (rolled plate, extrusion, bar stock) and cast alloys. Wrought alloys can of course be cast into simple blocks as well, but cast alloys allow to produce very intricate shapes such as engine blocks. This is possible because their high silicon content reduces the viscosity of the molten metal. However, the silicon forms very hard particles in the solidified material, which makes these alloys much more abrasive than wrought aluminium. Coated tools are therefore recommended for machining cast aluminium parts, while wrought alloys can be worked without difficulty using uncoated tools with sharp edges.

2024-T351, AlCu4Mg1

A medium-to-high strength alloy with good fatigue properties that is commonly used in aerospace parts subjected to high-cycle tension loads. Alloy 2124 is a variant with tighter control of impurities and similar machinability. Due to the high copper content, 2024 cannot be fusion welded and should be protected from corrosion. Typical Brinell hardness is 135 HB, yield strength 330 MPa, ultimate tensile strength 430 MPa (25 mm plate).

Similar: WNr 3.1355, UNI P-AlCu4.4MgMn, CSN 424203, GOST D16

5083-H116, AlMg4.5Mn

This alloy has very good resistance to corrosion but only moderate strength. In contrast to most other alloys, strength cannot be increased by heat treatment, but only by work hardening, for instance by cold forming processes such as rolling. 5083 is sold both as rolled and cast plate up to large thickness values. Cast plates have the advantage of high dimensional stability and very low residual stresses, but their yield strength is low due to the lack of cold work. Grade H116 is characterized by a very small degree of cold-work (such as might be the result from stretching for stress-relief) which would be typical of cast plates sold for machining applications. An alternative material with higher yield strength that is also available in plate form with low residual stresses is 7021.

Typical Brinell hardness is 75 HB, yield strength 120 MPa, tensile strength 260 MPa.

Similar: WNr. 3.3547, JIS 5082, UNS A95083, AFNOR 5183, CSN 424415, GOST AMg4.5

6061-T6, AlMg1SiCu, WNr. 3.3214

This is a very versatile alloy because it has moderate strength, good corrosion resistance, can be welded and machined with ease. As a heat-treatable alloy, 6061 is almost always sold in the warm-aged condition T6, i.e. heat treated to peak strength.

Cutting forces and power requirements in 6061 are low and its tendency to form build-up edges is less pronounced than 5083. Typical Brinell hardness is 90 HB, yield stress 240 MPa, tensile stress 290 MPa.

6082-T6, AlSi1MgMn

While 6061 is common in North America; the European alloy 6082 is almost identical. It features slightly higher strength and small differences in composition, but can also be welded and machines very well.

The yield (but not ultimate) strength of 6061 and 6082 is comparable to plain mild steels such as S235JR. Typical Brinell hardness is 95 HB, yield stress 240 MPa, tensile stress 295 MPa.

Similar: WNr. 3.2315, SS 4212

7021-T6, AlZn5.5Mg1.5, C330R

7021 is a specialized alloy that is primarily available in cast plates with very low residual stresses. As with cast plates of 5083, this has the advantage that the stock will not deform when machined, so that tight tolerances can be more easily achieved even if a large percentage of the stock is removed. The yield strength of 7021 is significantly higher than 5083 or even 6082 and is almost as high as 2024. Plates of this alloy are preferable to those made of 5083 when threads need to be cut or higher stress levels need to be supported.

Typical Brinell hardness is 120 HB, yield strength 315 MPa, tensile strength 350 MPa.

7075-T651, AlZn5.5MgCu

This is a widely available heat-treatable alloy that is available both in aerospace and commercial grades. Despite its high strength, it machines very well, although cutting forces are somewhat higher than for the other alloys. Plates and extrusions of 7075-T6 tend to carry some internal stresses. Removing a lot of material from one side of a thick plate will therefore lead to some deformation. This effect s reduced in stretched (T651) plates. 7075 cannot be fusion welded (due to cracking) and has relatively poor corrosion resistance, especially when loaded continuously in corrosive environments (SCC). The yield strength of 7075 is comparable or higher than that of annealed plain carbon steels such as C45, and its ultimate tensile strength will usually exceed that of standard mild steel, but it does not feature the same toughness.

Tools with extremely sharp edges such as those intended for use in plastics may be used in softer aluminium alloys, but their edges will likely chip in 7075. Typical Brinell hardness is 150 HB, yield strength 480 MPa, ultimate tensile strength 530 MPa (25 mm plate).

Similar: WNr. 3.4365, BS 2L95/2L96, UNS A97075, AFNOR A-Z5GU, UNI P-AlZN5.8MgCuCr PN AlZn6Mg2Cu, CSN 424222, GOST V95, SS 4440

EN AC-42100, A356-T6, AlSi7Mg0.3

Due to its strength and reasonable ductility, A356 is often used for load-bearing aluminium castings. The included material model is for the warm-aged condition (i.e. peak strength). Many other cast alloys have lower or similar strengths so that this model may be used as an indication for machining parts cast from other alloys.

Typical Brinell Hardness is 85 HB.

Similar: JIS AC4C, AFNOR A-S7G0.3, BS 2L99, WNr. 3.2371, GOST AL9, SS 4244

F357-T6, AlSi7Mg0.6

F357 is a variant of casting alloy A357 that does not contain Beryllium. It is a slightly stronger and tougher, but also more expensive alloy than A356. As for A356, this material model is for permanent mold castings; sand castings tend to have lower strength. Typical Brinell Hardness is 90 HB.

Similar: EN AC-42200, A357

Steel

This material category spans a very wide range of properties. First, steels can be categorized by the intentional presence of alloying elements (anything except iron and carbon) as

This material category spans a very wide range of properties. First, steels can be categorized by the intentional presence of alloying elements (anything except iron and carbon) as

- mild, or unalloyed steels, e.g. S235JR, 1018, 11SMn37, C45;

- low-alloyed steels with less than 5% alloying elements, such as 4140 +QT, 42CrMoS4 +A;

- high-alloyed steels, among them tool- and stainless steels, e.g. 420, 304, H13 and D2.

Furthermore, almost all steel alloys can be tailored to an application by heat treatment. It is common to machine steels in the annealed (soft) state. When high strength or hardness is required, the machined product is then hardened by heating to austenitization temperature followed by quenching and tempering. During that process, the part deforms slightly, so that a second finish machining pass may be necessary, but now in a much harder material.

Millalyzer can predict machining forces, tool life and stress for both passes, in annealed and hardened steel. If the alloy of interest is not available in the list below, it is often possible to use a similar alloy and let millalyzer scale material properties as described in the section on adjustments.

Mild steel

Most steel produced worldwide belongs to this category. There are many different grades and qualities, but all of them contain less than 0.25% carbon and no substantial alloying elements except for small amounts of Manganese and Silicon. This type of steel is highly suitable for welding and construction work, but usually does not have well-defined machining properties.

An example of a very widely used mild steel is S235JR. According to the standard (EN 10025), the required strength properties for as-rolled (+AR) and cold-drawn (+C) rod and bar are:

| Dimension | +AR Yield, MPa (ksi) | +C Yield, MPa (ksi) | +C Ultimate, MPa (ksi) |

|---|---|---|---|

| 5 - 10 mm | min. 235 (34) | min. 355 (51) | 470 - 840 (68 - 122) |

| 10 - 16 mm | min. 235 (34) | min. 300 (43) | 420 - 770 (61 - 112) |

| 16 - 40 mm | min. 225 (33) | min. 260 (38) | 390 - 730 (56 - 106) |

| 40 - 63 mm | min. 215 (31) | min. 235 (34) | 380 - 670 (55 - 97) |

| > 63 mm | min.195 (28) | min. 215 (31) | 360 - 640 (52 - 93) |

That is, the strength is allowed to vary over a wide range (195 - 355 MPa), because the composition is not tightly controlled and the degree of strain hardening due to cold work changes with manufacturing process. A cold-drawn 25 mm (1 in) bar must have a minimum yield strength of 260 MPa, but can very well be substantially stronger. Obviously, this makes it fairly difficult to predict machining forces for mild steel with any accuracy. There are therefore different material models; in many cases, actual milling forces will end up somewhere between results for these.

EN 1.0122, S235JR +AR

A model for S235JR in the as-rolled condition, that is, not accounting for hardening due to cold work. Sheet and bar stock that is meant to be used for bending or other cold-forming processes is likely in this state. Most cheap stock described as “hot-rolled mild steel” will likely have properties similar to this model.

Typical hardness is below 125 HB.

Similar: Q235, SS 1312, EN 1.0038, Fe 360 BFN, DIN RSt37-2, BS 40B, Ovako SB1312, IM2191, E250A, JIS E235B, JIS SS330, UNS K01500, GOST St3ks

EN 1.0419, AISI 1018 +C

This material model can be used when working with cold-formed stock, such as sheet, cold-rolled plates or cold-drawn bar. The material hardens somewhat during cold work so that machining forces increase. This model corresponds to a hardness of 190 HB and an approximate tensile strength of 640 MPa.

Similar: EN S275JR +C, DIN RSt44-2, Ovako SB1412, AFNOR 14-13-12E, BS 43A, ASTM A131 Grade E, JIS SWRCH18A, GOST St3sp, UNS G10180, SS 1414

EN 1.0736, AISI 1215, 11SMn37 +C

This is a free-machining grade that is commonly use in high-volume, unattended production. The significant content of sulphur and phosphorus reduces this material’s toughness, but also helps to break chips and reduces friction somewhat. Due to mediocre strength and toughness, his material is usually not selected for highly loaded components. It is not suitable for heat treatment or welding.

Typical Brinell hardness is 130 HB.

Similar: 9SMn36, UNS G12150, UNI CF9SMn36, JIS SUM25, AFNOR S300, ASTM A510 Grade 12L15

EN 1.7131, AISI/SAE 5115, 16MnCr5

16MnCr5 is a case hardening steel that is frequently employed for gear components and shafts, since it is designed to obtain a high surface hardness and wear resistance combined with good toughness properties in the core. This combination makes it suitable for machine parts that are subjected to high dynamic loads. At the same time, 16MnCr5 is still a relatively cost-effective material with only small amounts of alloying elements. Machinability is good and it can be welded in many applications.

The material used in the test from which this material model was identified was 16MnCr5, with slightly higher content of Manganese and Chromium compared to AISI/SAE 5115. The Brinell hardness of the test specimens was 240 HB, typical for stress-relieved small-diameter stock. Soft-annealing may be used to obtain about 180 HB to lower machining forces further.

Similar: AFNOR 16MC5, GB 5CrMn, GB 16MnCr, GB 20CrMnTi, SS2127, PN 15HG, BS 527M17, BS 590M17

EN 1.1730, AISI 1045, C45U +A

C45 is a widely available, low-cost, 0.45% carbon steel that is known for its homogeneity and good machinability. Cutting forces are moderate and relatively high cutting speeds can be used without excessive reduction of tool life. For that reason, it is a common choice for machined components with low to moderate strength requirements. Water-quenching and tempering can be employed to increase the strength of small sections (< 20 mm). Alternatively, C45 can also be case-hardened to increase wear resistance. Note that the material model is for the annealed state.

Typical Brinell hardness in the annealed state is 205 HB.

Similar: EN 1.1191, St70, AFNOR Y342, JIS S45C, BS 080M46/080A42, THYRODUR™ 1730, UNS G10450, SS 1650/1672, AISI 1043, ASTM A194 Grade 2, Cryodur™ 1730, Ovako Imatra™ 4M, GOST 45, UNE F.1145

EN 1.7225, AISI 4140, 42CrMo4 +QT

42CrMo4 is a versatile steel for structural applications. It is readily available both in the annealed (+A, see below) and quenched-and-tempered (+QT, this model) condition. Machining in the tempered state generates larger forces and reduces tool life, but it is still considered reasonably productive and definitely less demanding than machining of fully hardened tool steel. It can be a cost-effective process if the strength and hardness properties of 1.7225 +QT are sufficient for the application, so that additional heat treatment can be avoided. 42CrMo4 is not usually welded.

This material model can also be used as an approximation for pre-hardened mold and tool steels in the 33 HRC range, such as P20s or EN 1.2312, Daido PX4 or SSAB Toolox 33. Typical hardness in the tempered state for which this model is established is 310 HB or 33 HRC.

Similar: JIS SCM4/SCM4H/SCM440/SCM440H, AISI 4137/4142, ASTM A331/A505/A519/A646, AFNOR 42CD4, GOST 38HM, BS 708A42/708H37/708M40/709M40, SS 2244, UNS G41400, UNE F.1252, THYROQUENCH™ 7225, Firmodur™ 7225

EN 1.7227, AISI 4140, 42CrMoS4 +A

The only difference to 42CrMo4 is the controlled sulphur content that improves machining properties, especially for turning (chip breaking). In addition to that, some vendors also apply a Calcium deoxidation treatment that can reduce tool wear by eliminating hard inclusions. This model is for a hardness level of approximately 250 HB, and is a reasonable approximation for most tool steels that feature a comparable hardness level in the annealed state.

Similar: AFNOR 42CD4u, UNE F.1257, Ovako MoC410M™, Firmodur™ 7227

EN 1.2344, ASTM A681 H13, X40CrMoV5-1 +QT

1.2344 is a 5% chromium hot-work tool steel (used for e.g. extrusion and aluminium forging dies) that would usually be machined in the annealed state. This material model is for the hardened and tempered state and could be used to represent similar mold steels at this hardness. H13 can be hardened to 54 HRC or more; this model is for 1.2344 tempered to 46 HRC (about 430 HB) which has better toughness.

For machining H13 in the annealed state, prefer the model for EN 1.7227 +A.

Similar: AFNOR Z40CDV5, JIS SKD61, GOST 4H5MF1S, SS 2242, UNS T20811, Thermodur™ 2344, UNE F.5318, BS BH13

EN 1.2379, ASTM A681 D2, X153CrMoV12 +QT

1.2379 features better dimensional stability during hardening but does not retain hardness at high temperatures as well as hot-work steels. It can be polished very well and is hence used in injection molds. In the hardened state, it is very difficult to machine. This material model is for peak-hardened D2 at 62 HRC.

Similar: JIS SKD11, BS BD 2, AFNOR X160CrMoV12 1, GOST Ch12Mf, SS 2310, UNS T30402, Cryodur™ 2379

EN 1.4301, AISI 304, X5CrNi18-10

1.4301 is probably the most common stainless steel, widely available, easily weldable and with good corrosion resistance. As all austenitic stainless steels, it cannot be hardened by heat treatment but it is strongly strain-hardening and therefore relatively difficult to machine. AISI 304 is not ferromagnetic and conducts heat poorly compared to other steels. Thin stock (round bar, wire, sheet) that is not sold for machining may be in the cold-worked state and hence much harder than annealed stock. The closely related grade EN 1.4305 (AISI 303) contains sulphur to make it more suitable for machining. Typical Brinell hardness is 200 HB (annealed).

Similar: AFNOR Z7CN18.09, GOST 08H18N10, SS 2332, UNS S30400, JIS SUS304, PN 0H18N9, CSN 17240, GB 0Cr18Ni9, BS 304S15, Acidur™ 4301, UNE F.3504

EN 1.4021, AISI 420, X20Cr13

Just like other martensitic stainless steels that can be hardened by quenching, 1.4021 is somewhat less problematic to machine than 1.4301 - it has a less pronounced work-hardening tendency. Furthermore, AISI 420 is magnetic; its corrosion resistance is adequate for less challenging environments, improves with hardening, but remains somewhat worse than the austenitic alloys. 1.4021 can be polished after hardening. Typical Brinell hardness is 250 HB (annealed).

Similar: AFNOR Z20C13, GOST 20Kh13, REMANIT™ 4021, Corrodur™ 4021, SS 2303, UNS S42000, BS 420S29, PN 3H13, CSN 17023, GB 2Cr13, JIS SUS420J2, UNE F.3402

EN 1.4542, AISI 630, X5CrNiCuNb16-4

This is a precipitation-hardening stainless steel with high yield strength, good toughness properties and corrosion resistance. It is used for highly stressed parts such as turbine shafts, aircraft landing gear components and high-pressure pipes. Because the hardening mechanism is very different from carbon steels (actually more like aluminium alloys), it can not be annealed. Stock is supplied age-hardened or in the solution-treated condition (+AT) which still has a hardness of around 360 HB (39 HRC). The strain-hardening tendency is not as pronounced as with 1.4301, which can be beneficial for machining.

This particular material model is established for a hardness of 43 HRC, approximately corresponding to heat treatment H925 with yield strength 1070 MPa and tensile strength 1170 MPa.

Similar: 17-4 PH®, AFNOR Z7CNU17-04, JIS SCS24, UNS S17400, Acidur™ 4542, REMANIT™ 4542, GB 05Cr17Ni4Cu4Nb

Cast iron

EN GJL-200, SA278-200

GJL-200 is a cast iron with lamellar graphite. It is commonly used in applications where low cost or good damping properties are important. Typical Brinell hardness is about 140 HB.

GJL-200 is a cast iron with lamellar graphite. It is commonly used in applications where low cost or good damping properties are important. Typical Brinell hardness is about 140 HB.

Similar: GG-20, AFNOR Ft20D, JIS FC200, WNr. 5.1300 (DIN 1561), EN-JL-1030, GOST SCh20, UNS F12101, ASTM A48 30 B, PN Z120, GB HT20-40, GB HT200, UNI G20, SS 0120, IS FG200

EN GJS-400, ASTM A536 60-40-18

This is a cast iron with spherical graphite that exhibit very much better toughness and ductility than lamellar-graphite iron. Machining forces are slightly higher than for GJL-200. Typical Brinell hardness is approximately 160 HB.

Similar: GGG-400, JIS FCD 400-18L, WNr. 5.3104 (EN 1563), GOST VCh40, UNS F32800, BS 420/12, UNI GS400-12, SS 17-00, NEN GN42

Brass

EN CW614N, CuZn39Pb3

CW614N contains 3% lead (and is thus not suitable for RoHS/REACH compliant products), which makes it very suitable for high-speed machining. Many mass-produced turned brass parts are made from CW614N. Corrosion resistance is good and it is suitable for soldering, but not welding. Typical Brinell hardness is approximately 125 HB.

CW614N contains 3% lead (and is thus not suitable for RoHS/REACH compliant products), which makes it very suitable for high-speed machining. Many mass-produced turned brass parts are made from CW614N. Corrosion resistance is good and it is suitable for soldering, but not welding. Typical Brinell hardness is approximately 125 HB.

Similar: WNr. 2.0401, BS CZ121, GOST LS58-3, UNS C38500, SS 5170

EN CW724R, CuZn21Si3P

Often used in parts for electronic devices, automotive components and drinking water applications (faucets, fittings) because it does not contain lead. It has good strength and excellent machining properties. CW724R can be easily soldered and even welded. Typical Brinell hardness is approximately 150 HB.

Similar: UNS C69300, Cuphin 430 PbF

EN CC761S, CuZn16Si4-C

CC761 is a lead-free silicon brass used in die castings. Typical Brinell hardness is approximately 130 HB.

Similar: JIS SzBC2, WNr 2.0492, GOST LTS16K4, UNS C87500, TOFUFUR™

Exotic Alloys

Ti6Al4V, WNr. 3.7164

Ti6Al4V is a common alpha-beta titanium alloy that is often used for applications where strength, corrosion resistance and toughness are required. The same alloy is sometimes designated ‘Grade 5’. This alloy can be welded in protective atmospheres (or vacuum). Titanium needs to be machined at low cutting speeds (< 80 m/min), as tool flank wear increases rapidly at higher speeds. Typical Brinell hardness is approximately 240 HB.

Similar: UNS R56400, BS 2TA11, AMS 4920 Grade 5, GOST VT6

EN 2.4668, NiCr19Fe19Nb5Mo3

Inconel 718 is a Nickel-based alloy that can be used at high temperature for prolonged times, where steels would soften and creep. It also maintains high strength and good toughness at cryogenic temperatures. Properties change significantly with heat treatment; this material model is for the direct-aged condition. Typical hardness in this condition is approximately 44 HRC.

Similar: Inconel DA718, UNS N07718

Polymers

There are material models for Polyoxymethylene (POM, Delrin™, Acetal, Polyformaldehyde, Ramtal™, Duracon™, Kepital™, Polypenco™, Celcon™, Ultraform™, Kocetal™), Polyamide-6 (PA6, Nylon-6, Perlon™, Capron™, Durethan™), high-density Polyethylene (HDPE, PEHD, Polystone G™, Sanalite™), Polypropylene (PP, Ensipro™, Fortilene™, Proteus™, Versadur™) and Polycarbonate (PC, Makrolon™, Lexan™, Hydex™, Margard™, Tecanat™, Tuffak™, Zelux™, Hyzod™). POM, HDPE, and PA6 are frequently available in plate and round bar stock for milling; PC is often sold as glass-clear transparent or tinted translucent sheets.

Cutting forces in polymers are among the lowest of all materials; POM and HDPE are also characterized by favorably low friction coefficients. Because all of these materials melt at low temperatures, there is a risk of raised burrs, and, sometimes, molten stock clogging up the flutes. This is most likely to occur at high spindle speeds and low feed values (that is, very small chip thickness).

Almost all endmills will perform at least satisfactorily when cutting polymers. However, it is possible to use particular tools that are ground to a very sharp edge (high rake, small edge radius) in order to achieve good surface finish.

Wood

Wood differs significantly from all of the above materials because it is anisotropic, that is, most properties depend on the direction relative to the grain. Since millalyzer currently does not account for material anisotropy, the models for wood species intentionally aim to match the upper limits (worst case); this tends to occur when the cutting edge moves perpendicular to the grain direction. Actual cutting forces and power requirements will usually be lower, sometimes significantly. An exception to this rule is medium-density fibreboard (MDF), which should be reasonably isotropic.

Adjustments

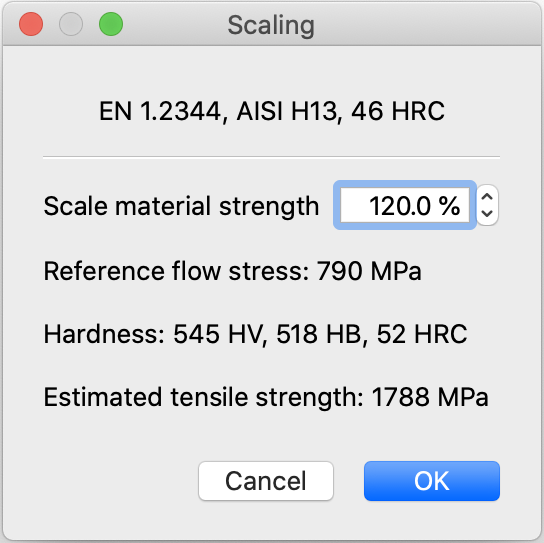

The implemented material models cover a wide range of different properties, but cannot exactly represent all available materials. Steel in particular is used in very many alloys and heat treatment states; should your specific alloy not be listed above, it is still possible to start from one of the recommended models in the table below, and use the stress scaling function to adjust the material properties. The stress scaling function is activated by clicking on the blue Material link to the left of the material selection box and opens the window shown on the right.

The implemented material models cover a wide range of different properties, but cannot exactly represent all available materials. Steel in particular is used in very many alloys and heat treatment states; should your specific alloy not be listed above, it is still possible to start from one of the recommended models in the table below, and use the stress scaling function to adjust the material properties. The stress scaling function is activated by clicking on the blue Material link to the left of the material selection box and opens the window shown on the right.

Example

To check for permissible feed and engagement when milling SKD6 hot-work tool steel (EN 1.2343, X37CrMoV5-1, H11), hardened to 52 HRC, select the material model for EN 1.2344 (H13), then adjust the stress scaling factor to 120% in order to reach an approximate hardness of 52 HRC as displayed in the screenshot above. This scaling factor will remain active for all further computations unless you switch to another material.

Baseline models for adjustments

The table below can be used as a baseline for low-alloyed carbon and tool steel, as well as most of the martensitic steels (12% or more chromium, low nickel content). For austenitic or stainless duplex steels, use the model for EN 1.4301 (AISI 304) as a baseline and scale to match hardness.

| Hardness | Recommended material model |

|---|---|

| < 170 HB | S235JR |

| 170 - 230 HB | C45U, AISI 1045 |

| 230 - 270 HB | EN 1.7227 +A |

| 270 HB - 38 HRC | EN 1.7225 +QT |

| 38 - 55 HRC | EN 1.2344, H13 |

| > 55 HRC | EN 1.2379, D2 |

| Annealed martensitic | EN 1.4021, AISI 420 |

| Annealed austenitic | EN 1.4301, AISI 304 |

| Iron with lamellar/vermicular graphite | EN GJL-200 |

| Iron with nodular/spherical graphite | EN GJS-400 |