Optimization

Quite often, the machining forces are not the primary concern, but rather how to choose machining parameters which yield the shortest machining time while staying within the limitations of machine and setup. For this purpose, millalyzer provides four functions that can be reached from the Edit menu, Recommend AE (radial engagement), Recommend AP (axial engagement), Recommend feed and Optimization.

Procedure

Spindle speed (N, VC) and feed (VF, FZ or HEX) will not be modified by the AP and AE recommendation functions, and this has a simple reason. With the models that are available today, an increase in speed will always improve productivity; therefore, any optimization that is unaware of further constraints would invariably select the highest possible spindle speed. In reality, speed is limited by tool heating (for steel, exotic alloys or dry machining); this limit depends strongly on coating properties and coolant flow. Therefore, it is recommended to follow the manufacturer’s published cutting speed recommendation to select spindle speed.

Due to the development of plastic stress with strain (strain hardening) and strain rate (rate hardening), an optimization that trades engagement against feed trends toward the maximum available feed, because cutting stresses in ductile metals decrease with increasing chip thickness. The magnitude of this effect differs between materials.

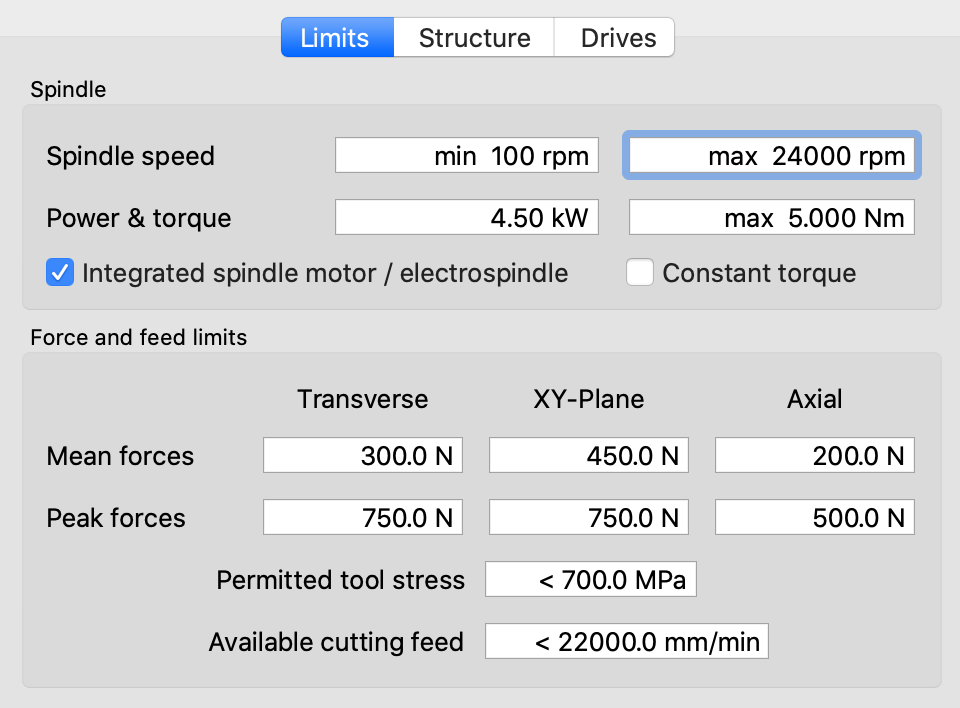

Machine limits

Before a parameter can be adjusted, there needs to be a limit up to which any increased loads can be accepted. Use the menu item Machine limits in the Edit menu to prescribe permitted mechanical power, a torque limit and maximum allowed peak and mean forces. The meaning of the parameters is explained in detail in the chapter on machine limits.

Before a parameter can be adjusted, there needs to be a limit up to which any increased loads can be accepted. Use the menu item Machine limits in the Edit menu to prescribe permitted mechanical power, a torque limit and maximum allowed peak and mean forces. The meaning of the parameters is explained in detail in the chapter on machine limits.

Unless more information is available, the recommended approach is to re-compute a know-good milling operation, and then use the loads computed for that case as limits:

- Setup a simple side-milling operation with a well-known tool using one of the workpiece materials available in millalyzer.

- Run at least three identical cuts along the same workpiece side to eliminate the effect of mean transverse tool deflection.

- Repeat the above at increasing feed (e.g. using feed override) until surface quality becomes unacceptable or noise indicates chatter.

- Perform a simulation with millalyzer using the highest acceptable feed and use the computed forces as machine limits.

Adaptive/dynamic milling: Recommend AE (radial engagement)

Many times, radial engagement (or optimal load, or stepover) is the only parameter that can be freely varied during programming, because the geometry of cut or tool do not permit any increase in axial depth of cut. The function Recommend AE will find the highest possible value of radial engagement that is possible without exceeding the configured limits.

Note

Changing AE also has an effect on the uncut chip thickness HEX. Remember that you can set feed by prescribing a certain value of this chip-load (HEX). So, if the HEX constraint on feed is active, that is, the label Uncut chip [HEX] is displayed in bold, then the Recommend AE function will automatically adjust the linear feed speed when modifying radial engagement. Sometimes, when the machine force limits are low, this can result in small radial engagement and very large feed values.

Note that when the operation is a helical ramp, reducing radial engagement also forces a smaller path radius. This is usually not intended, and it’s therefore better to use the Recommend AP or Recommend feed option.

This function can also be invoked by the shortcut ALT+W (or option+W on macOS; “optimize width of cut”).

Slotting: Recommend AP (axial engagement)

When cutting slots, only the depth can be varied because the axial engagement is locked to be equal to the tool diameter. The function Recommend AP will simply increase or reduce the value of AP until the first of the configured limits is hit. Of course, this function can also be used with any other values of radial engagement.

This function can also be invoked by the shortcut ALT+D (or option+D on macOS; “optimize depth of cut”).

Recommend feed

In a similar fashion, Recommend feed retains the set engagement dimensions and pushes the feed up to match the defined machine limits. This can result in very large feed values that exceed the available chip space of the flutes, as well as very small values that could cause rubbing.

This function can also be invoked by the shortcut ALT+F (or option+F on macOS; “optimize feed”).

Parameter optimization

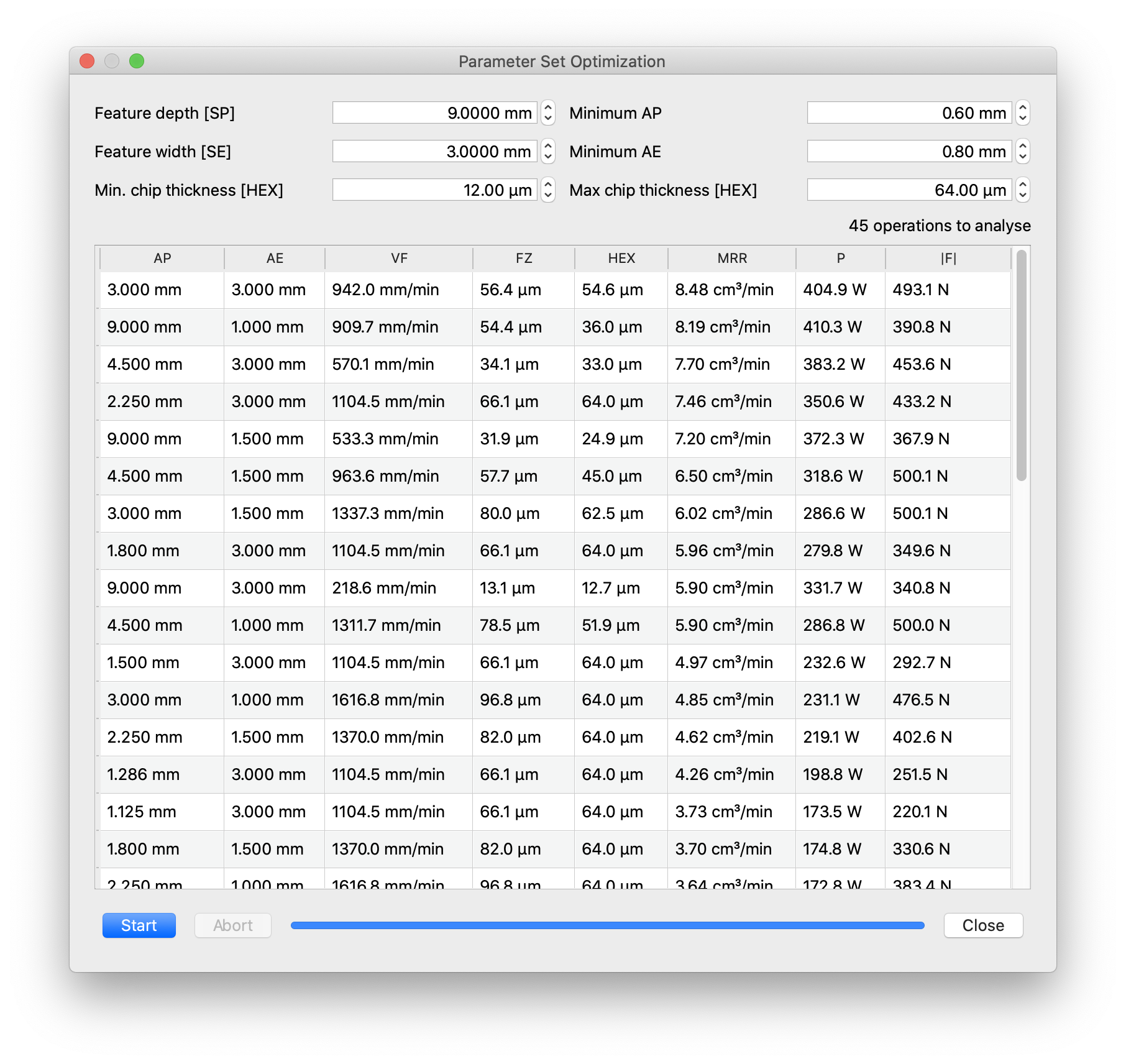

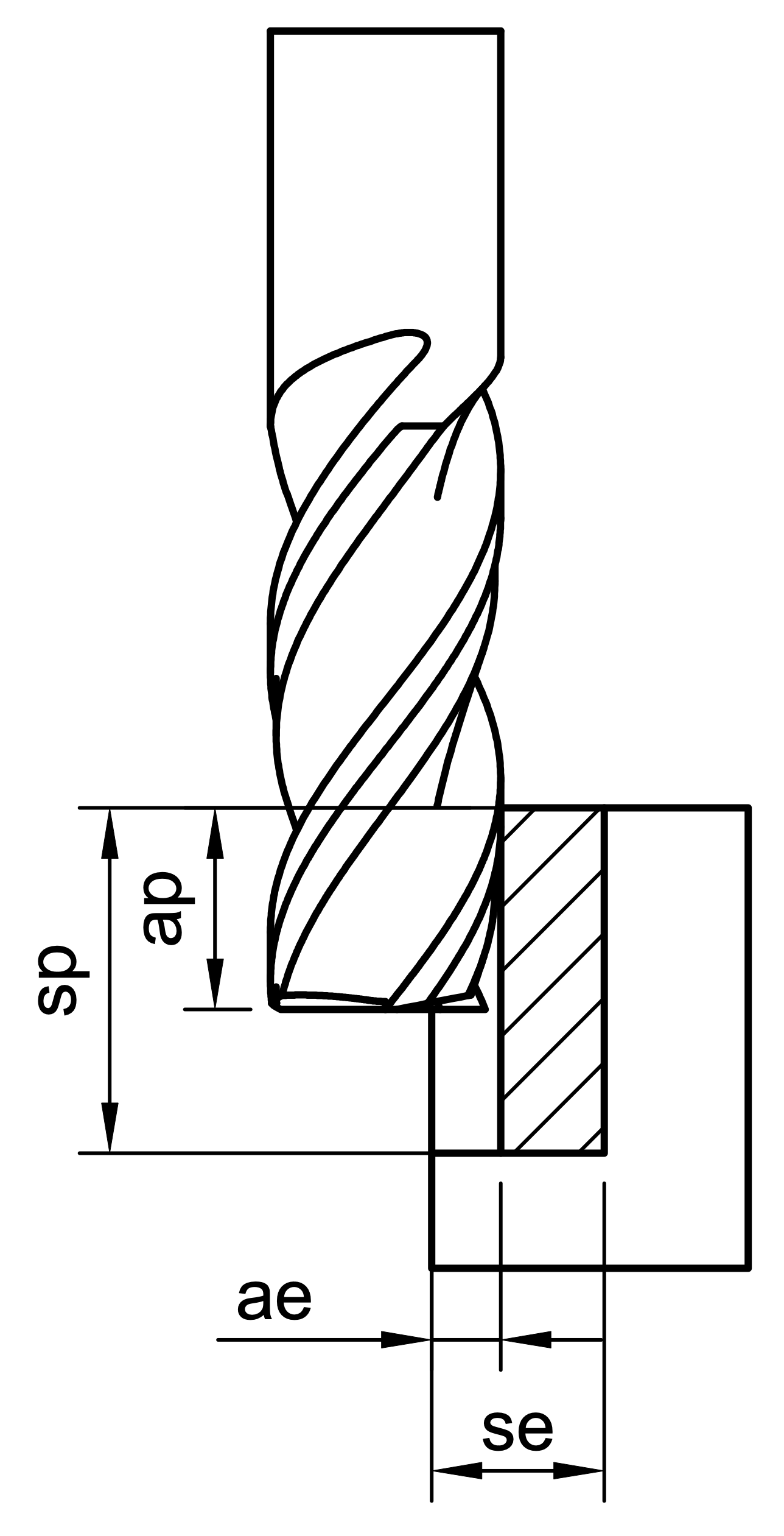

When neither the engagement (AP, AE), nor the feed or chipload is known, then a full parameter optimization can be performed (Utility - Optimization). For this option, the user needs to specify how much material is to be removed in total, both in axial (depth, SP) and radial direction (width, SE). The fastest possible process has equal passes (e.g. three depth passes all with AP = SP/3), which means that the choices for engagement (AP and AE) need to be integer fractions of the feature dimensions. Parameter optimization finds the number of passes in depth and width direction along with the best corresponding feed such that the total machining time is minimal.

For the case in the screenshot above, a 9 mm deep (SP) feature is to be milled and 3.0 mm (SE) of material are to be removed in the lateral direction. The 8-mm-endmill used is large enough for a single pass, but then the feed would need to be reduced to very low values (here: 218 mm/min) in order to stay within the machine limits. Running multiple passes in depth and/or laterally is more efficient. In this particular case, the difference between the first two options is small, but the second generates much smaller in-plane forces, so that it is probably preferable.

For the case in the screenshot above, a 9 mm deep (SP) feature is to be milled and 3.0 mm (SE) of material are to be removed in the lateral direction. The 8-mm-endmill used is large enough for a single pass, but then the feed would need to be reduced to very low values (here: 218 mm/min) in order to stay within the machine limits. Running multiple passes in depth and/or laterally is more efficient. In this particular case, the difference between the first two options is small, but the second generates much smaller in-plane forces, so that it is probably preferable.

Material and tool are selected in the main window, before the optimization window is opened, and will remain in use until the parameter optimization dialog is closed. In addition to feature depth/width, the user can choose to specify the minimum desired engagement (AP and AE) which put an upper limit on the number of passes. Very small engagement values are often not beneficial because the secondary machining times (primarily for repositioning moves) increase too much. Millalyzer will pre-set reasonable values for minimum and maximum chip thickness (HEX, effective chipload), which you also can change if desired.

Once the run is started, an optimal feed value is computed for each possible engagement, so that the resulting operation conforms to all configured limits (spindle torque, tool stress, force limits, maximum cutting feed). All valid results are then listed in the table as they become available, sorted by decreasing material removal rate.

Double-click on any of the result rows to copy the operation parameters to the main analysis window.

Note

At present, the recommendations do not take the machine dynamics into account. That means that the recommended cutting parameters may cause chatter, unless the user-defined force limits are set sufficiently low.